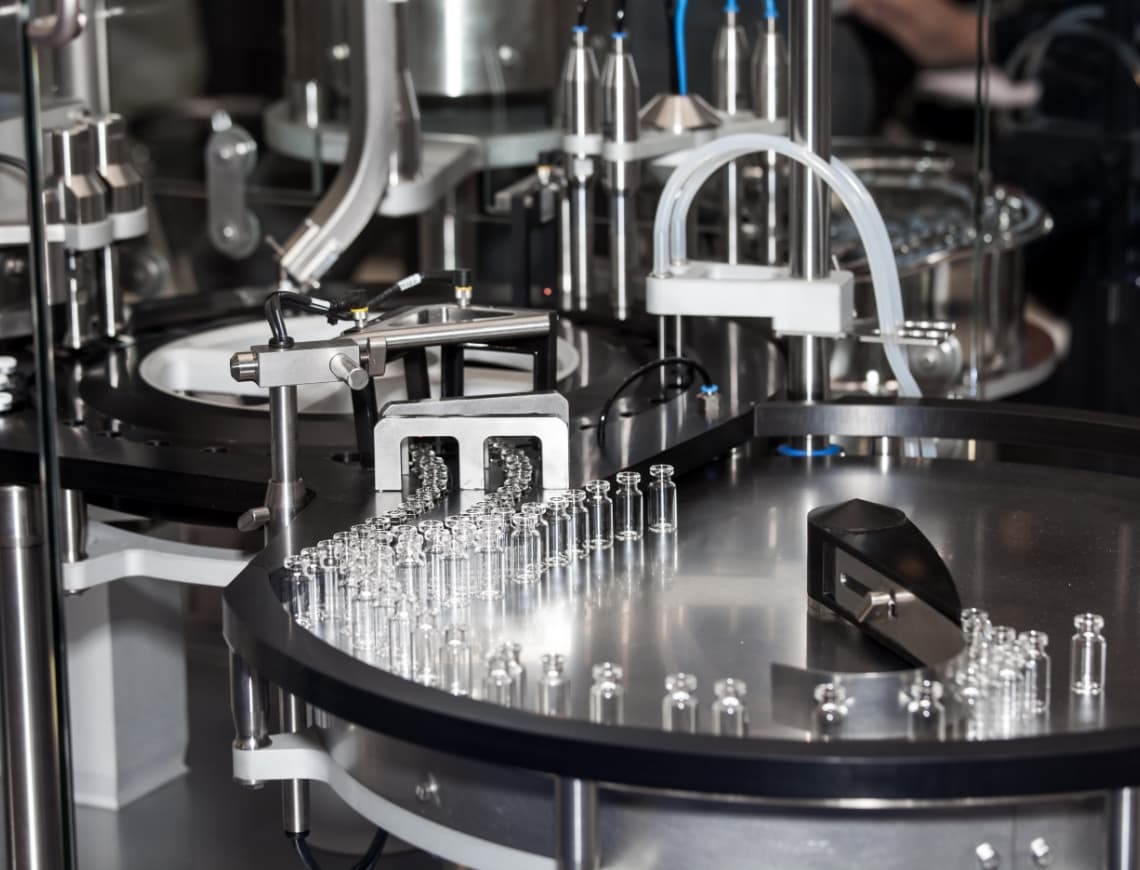

At Zilyc, we deliver practical LEAN Manufacturing solutions tailored to the unique demands of the life sciences sector. With over 20 years of experience, we help companies streamline processes, reduce costs, and ensure regulatory compliance through structured, measurable improvements. From manufacturing SOPs to cross-functional training, we build efficient systems that scale.

Establish meaningful KPIs and introduce data-driven performance tracking. Our LEAN strategies empower your team to identify and eliminate inefficiencies across operations, driving measurable improvements in productivity. Daily management meetings will help facilitate insurance of sustainability.

We facilitate customized Kaizen events and provide LEAN methodology training across R&D, manufacturing, supply chain, QC, and QA. These workshops are designed to uncover root causes and align teams on continuous improvement goals. Through value stream mapping, we identify areas of improvement and prioritize resources for specific Kaizen events.

Zilyc supports the implementation of RCA tools like DIVE problem-solving tools, 5 Whys, and Cause and Effect Diagrams to resolve recurring issues. Our standardized approaches empower your teams to solve problems collaboratively and prevent future setbacks.

Our team builds compliant SOPs and documentation tailored to your operations. We ensure your processes align with FDA and ISO expectations, offering clear, replicable standards that ensure quality and safety.

We create comprehensive LEAN roadmaps for your manufacturing environment—whether you're starting fresh or optimizing an existing system. Our approach integrates people, processes, and platforms for long-term success.

Implementing LEAN principles in regulated industries goes beyond reducing waste, it’s a strategic framework that improves quality, accelerates innovation, and ensures long-term sustainability.

LEAN Manufacturing improves efficiency by eliminating waste, enhancing workflow, and empowering teams to contribute to process improvement. This leads to lower costs, faster delivery times, and higher product quality.

Depending on your organization’s size, complexity, and readiness, LEAN implementation can range from a few weeks for pilot groups to several months for enterprise-wide adoption. Zilyc provides structured rollout plans to ensure sustainable transformation.

Not at all. LEAN complements compliance efforts by standardizing processes and reducing errors. Our systems are designed to align with FDA and ISO requirements while improving performance.

Biotech startups, diagnostics manufacturers, and established pharmaceutical firms alike benefit from LEAN strategies. Whether you're scaling or stabilizing, LEAN enhances control and agility.

Ready to implement LEAN strategies that reduce waste, improve efficiency, and enhance quality?

Contact Zilyc today to learn how our expert-led LEAN Manufacturing consulting can help you build smarter, faster, and more resilient operations.